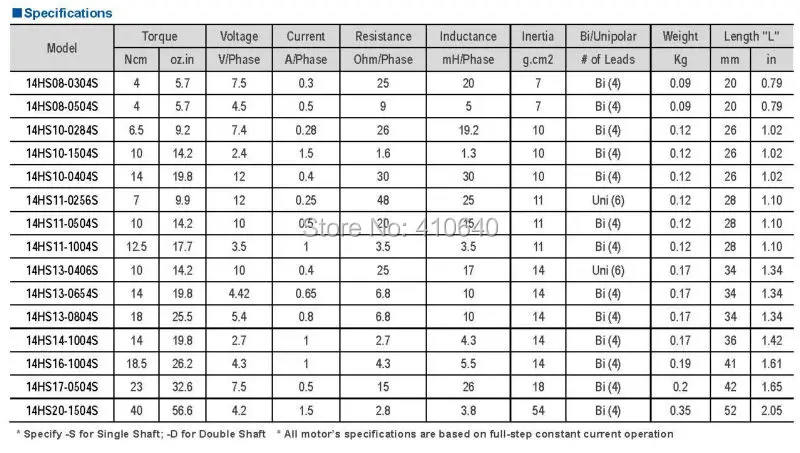

The 14HS Stepper Motor was developed primarily for users who have a restricted installation depth available and where a stepper motor with a construction size of 28 mm Stepper Motor is too long and a construction size of 39 mm Stepper Motor is too big. With the highest possible torque the Nema 14HS Stepper Motor series offers a high resolution and is deployed with low-priced power drive for applications in the precision device construction. We have 8-Lead Stepper Motor that can be connected in all possible configurations: series, unipolar, or parallel, to allow the maximum flexibility for your application. We can also customize Nema 14 Stepper Motor's winding to perfectly match voltage, current, and maximum operating speed to meet your requirements.

Inject printers, Analytical and Medical Instruments, Textile Equipment, Embroidery Machine, Precision Telescope Positioning Systems, High Speed Dome Camera and 3D Robotic

A stepper motor (or step motor) is a brushless DC electric motor that divides a full rotation into a number of equal steps. The motor's position can then be commanded to move and hold at one of these steps without any feedback sensor (an open-loop controller), as long as the motor is carefully sized to the application.

Switched reluctance motors are very large stepping motors with a reduced pole count, and generally are closed-loop commutated.

Fundamentals of operation

DC brush motors rotate continuously when voltage is applied to their terminals. Stepper motors, on the other hand, effectively have multiple "toothed" electromagnets arranged around a central gear-shaped piece of iron. The electromagnets are energized by an external control circuit, such as a microcontroller. To make the motor shaft turn, first, one electromagnet is given power, which magnetically attracts the gear's teeth. When the gear's teeth are aligned to the first electromagnet, they are slightly offset from the next electromagnet. So when the next electromagnet is turned on and the first is turned off, the gear rotates slightly to align with the next one, and from there the process is repeated. Each of those rotations is called a "step", with an integer number of steps making a full rotation. In that way, the motor can be turned by a precise angle.

Types

There are four main types of stepper motors:

1:Permanent magnet stepper (can be subdivided into 'tin-can' and 'hybrid', tin-can being a cheaper product, and hybrid with higher quality bearings, smaller step angle, higher power density)

2:Hybrid synchronous stepper

3:Variable reluctance stepper

4:Lavet type stepping motor

Permanent magnet motors use a permanent magnet (PM) in the rotor and operate on the attraction or repulsion between the rotor PM and the stator electromagnets. Variable reluctance (VR) motors have a plain iron rotor and operate based on the principle that minimum reluctance occurs with minimum gap, hence the rotor points are attracted toward the stator magnet poles. Hybrid stepper motors are named because they use a combination of PM and VR techniques to achieve maximum power in a small package size.

Two-phase stepper motors

There are two basic winding arrangements for the electromagnetic coils in a two phase stepper motor: bipolar and unipolar.

Unipolar motors

A unipolar stepper motor has one winding with center tap per phase. Each section of windings is switched on for each direction of magnetic field. Since in this arrangement a magnetic pole can be reversed without switching the direction of current, the commutation circuit can be made very simple (e.g., a single transistor) for each winding. Typically, given a phase, the center tap of each winding is made common: giving three leads per phase and six leads for a typical two phase motor. Often, these two phase commons are internally joined, so the motor has only five leads.

A microcontroller or stepper motor controller can be used to activate the drive transistors in the right order, and this ease of operation makes unipolar motors popular with hobbyists; they are probably the cheapest way to get precise angular movements.

Unipolar stepper motor coils

(For the experimenter, the windings can be identified by touching the terminal wires together in PM motors. If the terminals of a coil are connected, the shaft becomes harder to turn. one way to distinguish the center tap (common wire) from a coil-end wire is by measuring the resistance. Resistance between common wire and coil-end wire is always half of what it is between coil-end and coil-end wires. This is because there is twice the length of coil between the ends and only half from center (common wire) to the end.) A quick way to determine if the stepper motor is working is to short circuit every two pairs and try turning the shaft, whenever a higher than normal resistance is felt, it indicates that the circuit to the particular winding is closed and that the phase is working.

Bipolar motor

Bipolar motors have a single winding per phase. The current in a winding needs to be reversed in order to reverse a magnetic pole, so the driving circuit must be more complicated, typically with an H-bridge arrangement (however there are several off-the-shelf driver chips available to make this a simple affair). There are two leads per phase, none are common.

Static friction effects using an H-bridge have been observed with certain drive topologies.[2]

Dithering the stepper signal at a higher frequency than the motor can respond to will reduce this "static friction" effect.

Because windings are better utilized, they are more powerful than a unipolar motor of the same weight. This is due to the physical space occupied by the windings. A unipolar motor has twice the amount of wire in the same space, but only half used at any point in time, hence is 50% efficient (or approximately 70% of the torque output available). Though a bipolar stepper motor is more complicated to drive, the abundance of driver chips means this is much less difficult to achieve.

Higher-phase count stepper motors

Multi-phase stepper motors with many phases tend to have much lower levels of vibration,[3] although the cost of manufacture is higher. These motors tend to be called 'hybrid' and have more expensive machined parts, but also higher quality bearings. Though they are more expensive, they do have a higher power density and with the appropriate drive electronics are actually better suited to the application[citation needed]. Computer printers may use hybrid designs.

Stepper motor driver circuits

Stepper motor performance is strongly dependent on the driver circuit. Torque curves may be extended to greater speeds if the stator poles can be reversed more quickly, the limiting factor being the winding inductance. To overcome the inductance and switch the windings quickly, one must increase the drive voltage. This leads further to the necessity of limiting the current that these high voltages may otherwise induce.

Microstepping

What is commonly referred to as microstepping is often "sine cosine microstepping" in which the winding current approximates a sinusoidal AC waveform. Sine cosine microstepping is the most common form, but other waveforms can be used.[4] Regardless of the waveform used, as the microsteps become smaller, motor operation becomes more smooth, thereby greatly reducing resonance in any parts the motor may be connected to, as well as the motor itself. Resolution will be limited by the mechanical stiction, backlash, and other sources of error between the motor and the end device. Gear reducers may be used to increase resolution of positioning.

Step size repeatability is an important step motor feature and a fundamental reason for their use in positioning.